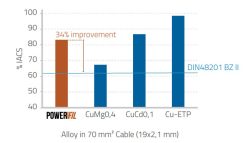

Lamifil yet again reinforces its position at the forefront of innovation with PowerFil®. This unique alloy offers significantly superior properties compared to conventional CuMg. With 23% more conductivity compared to CuMg 0,5, PowerFil® is the top alternative for a Cd-free world.

PowerFil®

- Minimised energy loss. PowerFil® allows operators to save up to 12,000 euros per km during the lifetime of a messenger wire.

- Reduced CO2 and higher efficiency. This ‘green’ alloy offers approximately 23% better resistance than standard CuMg 0,5 alloys.

- Increased rail capacity. PowerFil® offers less resistance and heat losses, allowing more trains to run on the same track.

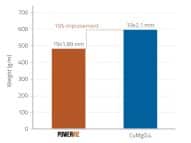

- Less use of copper. PowerFil® creates opportunities for leaner cable designs with smaller sections offering the same characteristics, allowing operators to save copper weight and costs.

COMPARISON OF CONDUCTIVITY (% IACS ) VS LAMIFIL’S POWERFIL®

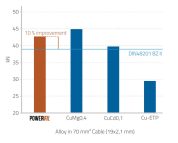

COMPARISON OF BREAKING LOAD (KN) VS LAMIFIL’S POWERFIL

COMPARISON OF WEIGHT (G/M), FOR THE SAME ELECTRICAL RESISTANCE, CUMG VS LAMIFIL’S POWERFIL®