1906-1929

Glass & trucks made in Hemiksem

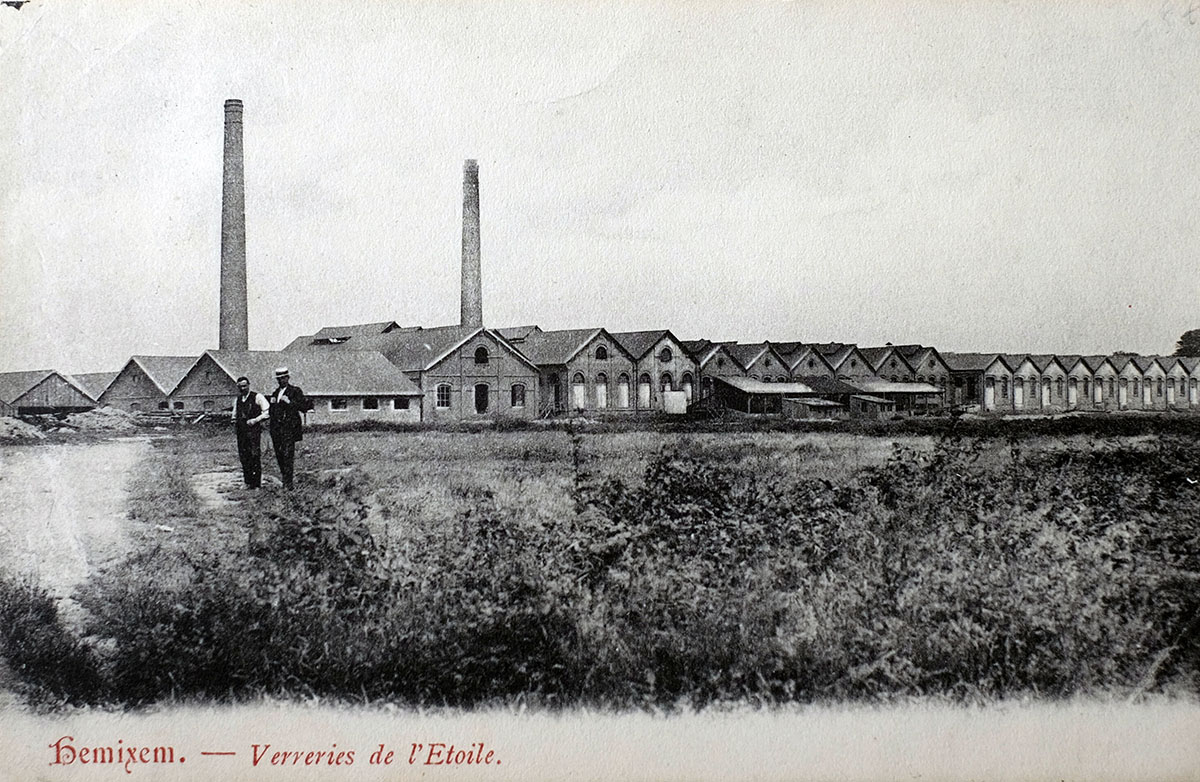

Glassworks "Verreries de l'Etoile"

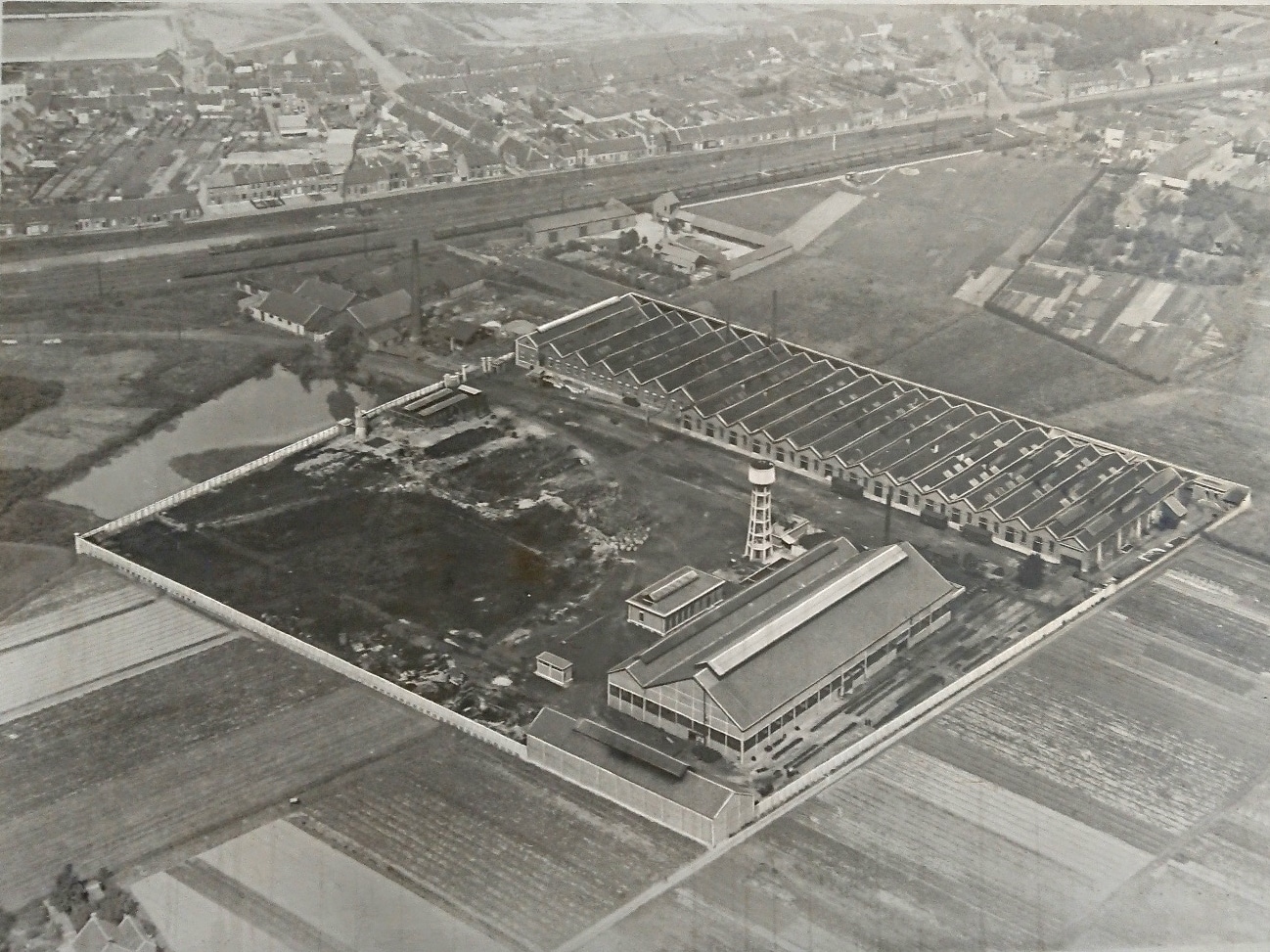

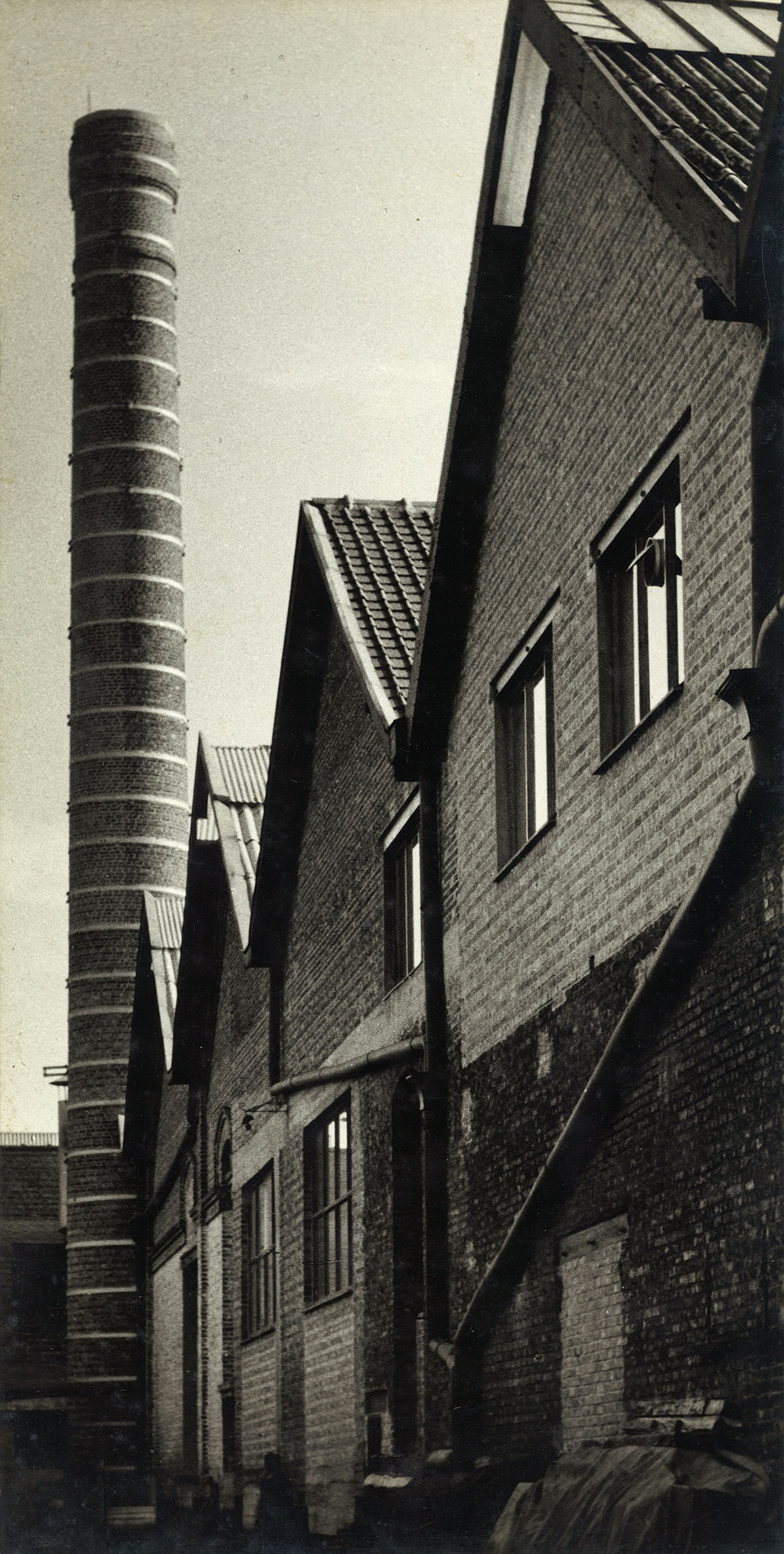

The story of Lamifil goes back to the early beginnings of the previous century. On 31 August 1906, glassworks Verreries de l’Etoile were started up on the current terrains of Lamifil.

The glass-blowers were recruited primarily in the Walloon region of Belgium. They went to live in a nearby street, which was later given the name rue de l’Etoile or Sterrelaan, according to the company name. Many of these glass-blowers did not thrive in these surroundings and quickly returned to their home regions. The young glassworks had to declare bankruptcy after just half a year.

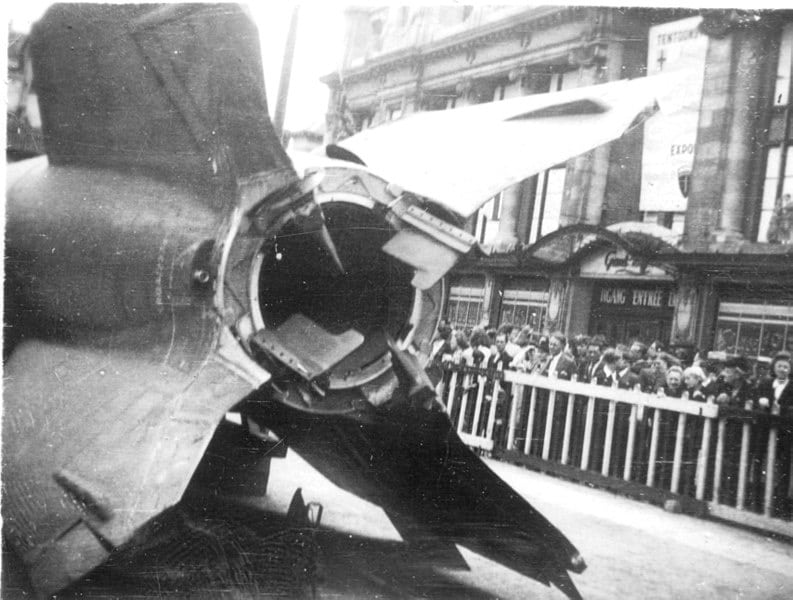

Auto traction & Minerva

In 1920, the grounds were taken over by Auto Traction, a builder of freight lorries and motor coaches. Minerva, the legendary Belgian automobile brand, became sole owner of the factories in 1925. The freight lorries were thereafter given the brand name ‘Minerva – Auto Traction’.

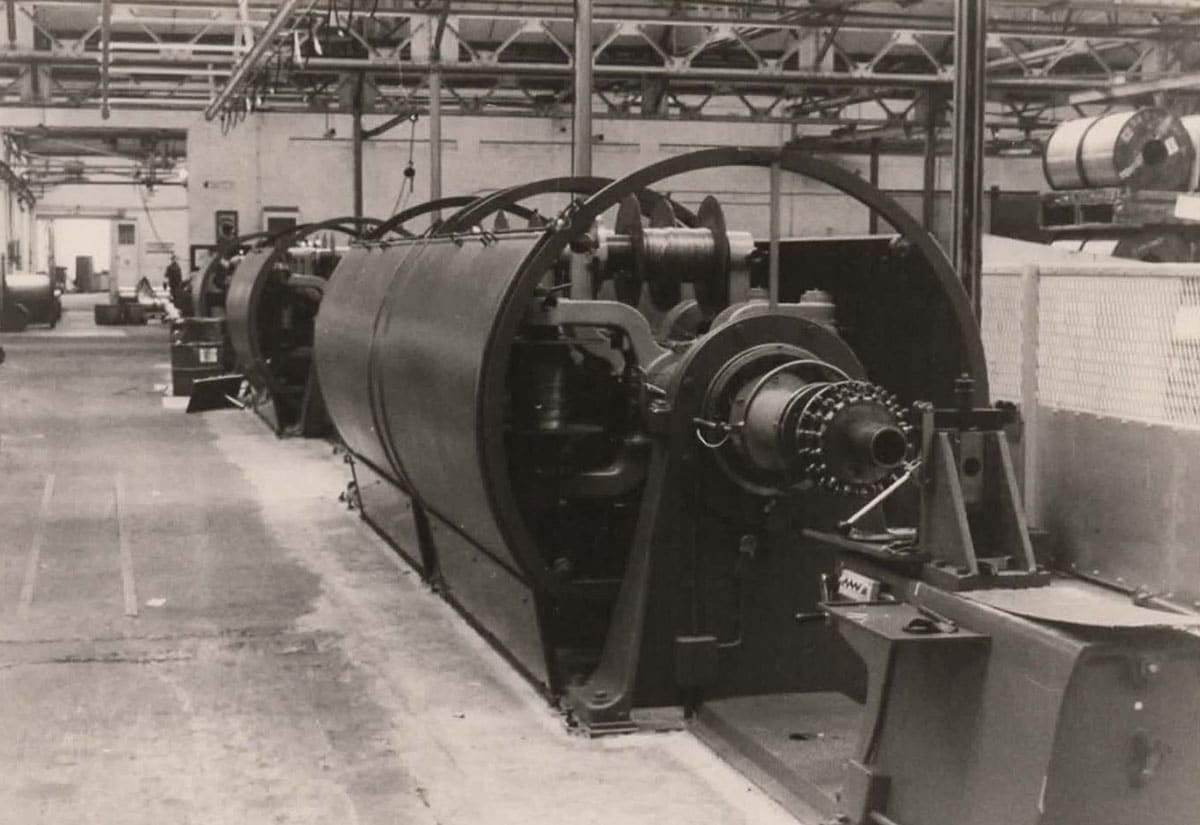

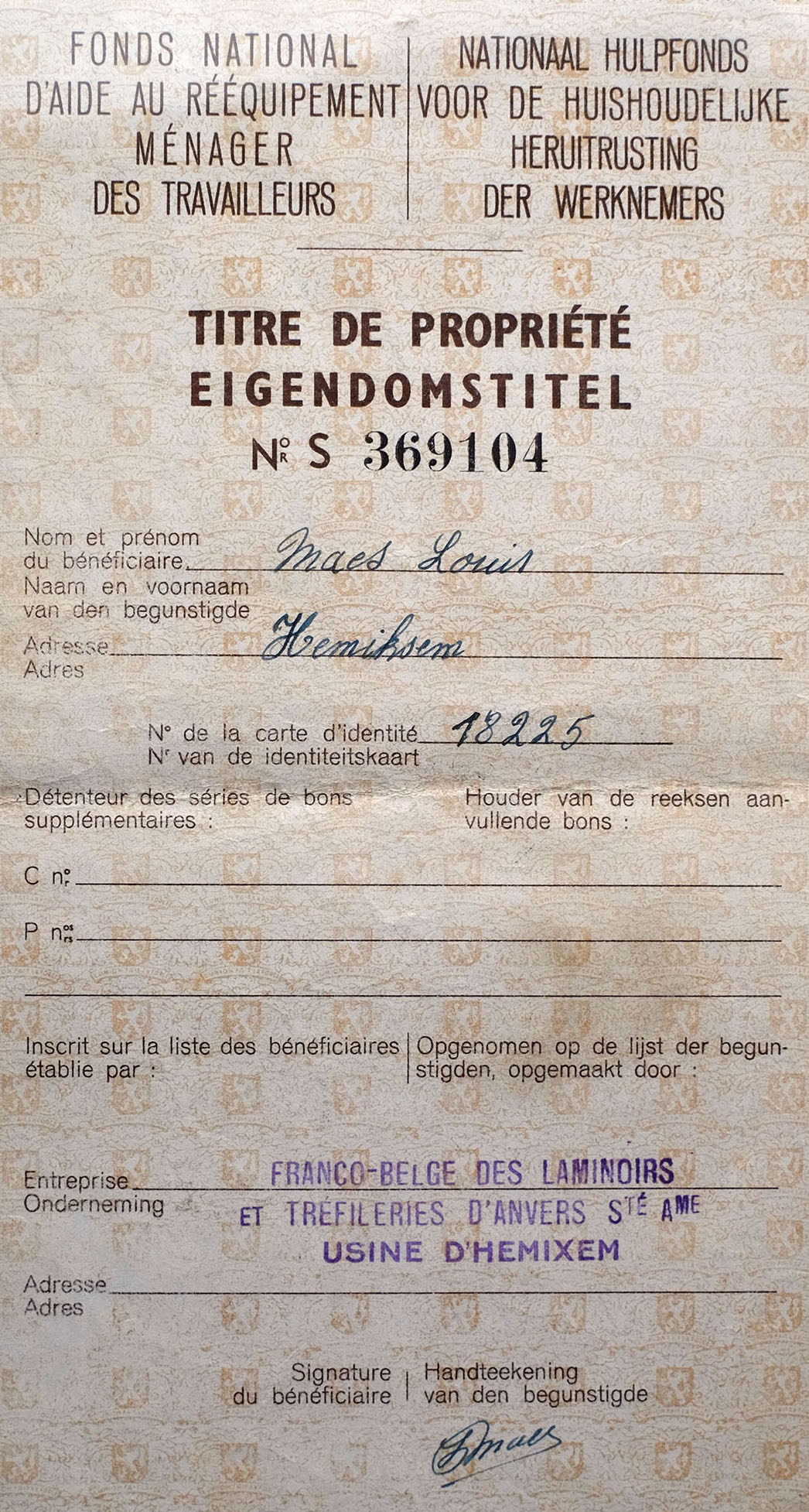

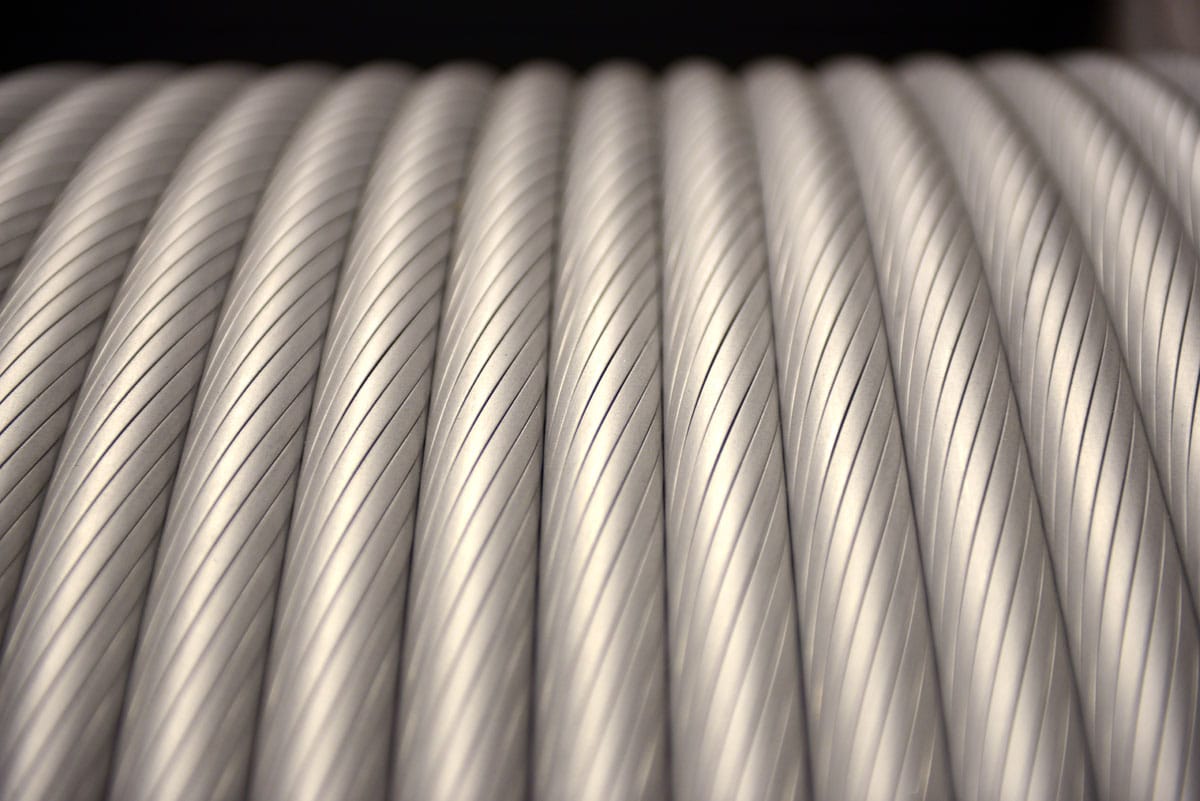

Tréfileries, Laminoirs et Fonderies de Chauny

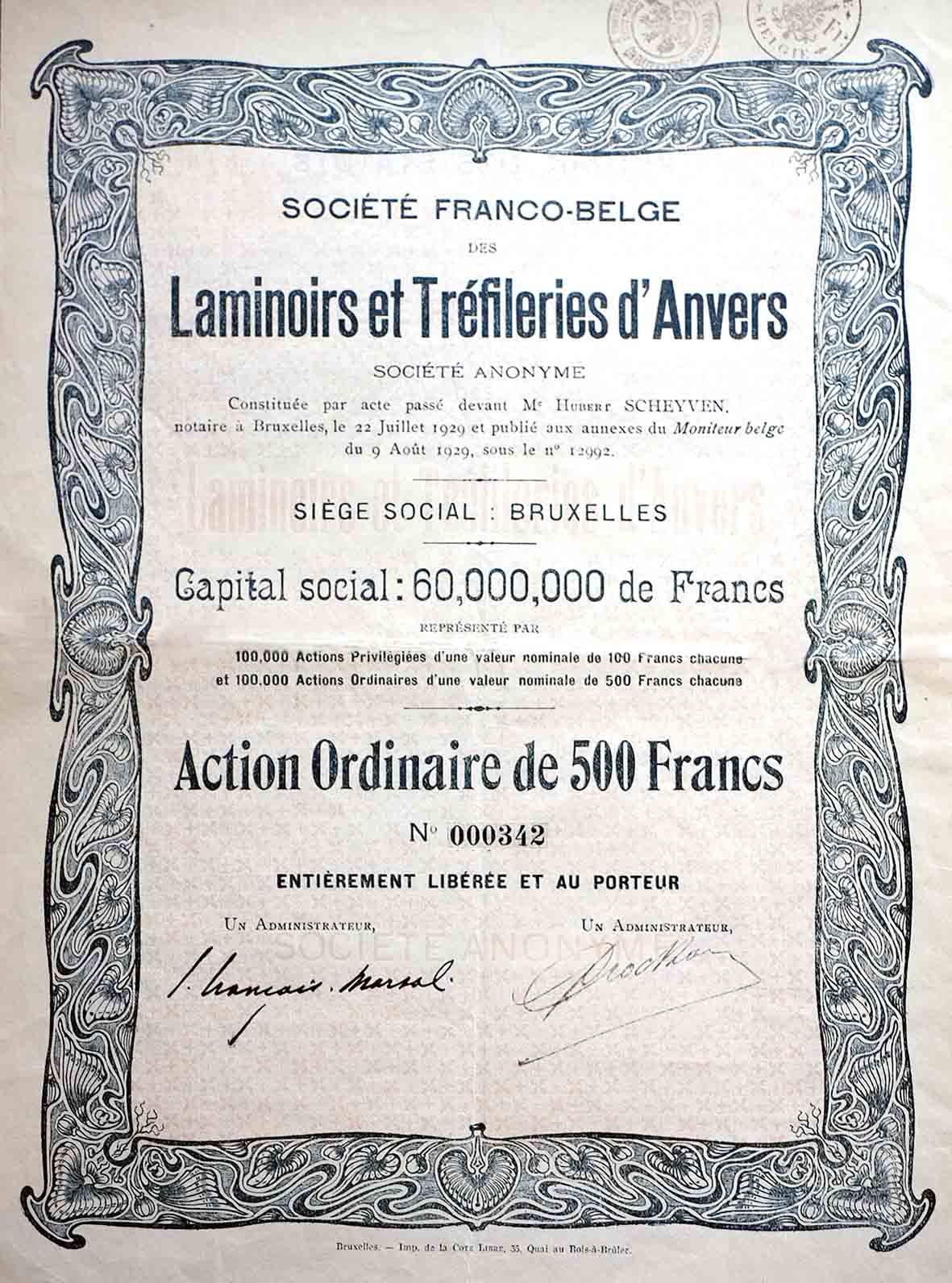

In 1928, the grounds and buildings came into the hands of the French company Tréfileries, Laminoirs et Fonderies de Chauny from Paris. Not much later, these were used for the establishment of what became known first as ‘Franco-Belge’, and today as Lamifil.