HIGH QUALITY PRODUCTS

We offer a comprehensive range of aluminium and copper products and their alloys, designed to improve efficiency and add value for our clients. Lamifil advises on the best match for your needs, and where appropriate, even design new products. By controlling the production process from wire rod casting to finished product, we can assure our clients of widest range, reliability and quality.

Aluminium speciality wires

Using state-of-the art continuous melting and casting facilities, Lamifil produces aluminum wire products in a diverse range of alloys, shapes and diameters on coil for electrical and mechanical applications. Our products’ homogenous material properties as well as our continuous and optimized production process enable manufacturers to decrease production downtime, eliminate losses and improve efficiency.

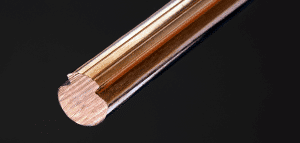

Copper speciality wires

Our unique continuous upcasting production process for copper products offers multiple benefits compared to production using billets. Our consistent product quality, stability and delivery on coil allows customers to produce more cost efficiently and reliably, while keeping full control of their production processes.

Overhead conductors

Innovations like the use of shaped wires instead of round and advanced alloys and composites, lead to revolutionary products for electricity suppliers and distributors. Increasing capacity, increasing efficiency, lowering costs and adding environmental friendliness are some of the advantages we offer. Discover our products and innovations here or read more about how we connect the dots for your conductor challenge.

Catenary Wires

Lamifil has shifted away from copper commodity railway products. For railway applications, our PowerFil® alloy is now the cornerstone of our catenary wire product offering. PowerFil® is a unique alloy with superior properties compared to conventional CuMg. It offers 23% more conductivity than CuMg 0,5. Its benefits include minimized energy loss, reduced CO2 and higher efficiency, increased rail capacity and less use of copper.