- Our unique new test bench allows up to six simultaneous tests, each of which can be performed under different conditions, including adjustable force and amplitude.

- Our mechanical fatigue tests are fully accredited.

- Our lab has over 5 years of experience with mechanical fatigue testing for numerous references worldwide.

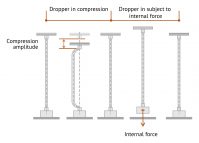

- The sample dropper wire is embedded in copper fixing sleeves or clamped in specific devices in a test bench;

- Weight is added to the test bench;

- Each cycle consists of an alternate compression and load cycle. The dropper cable is subjected to sinusoidal oscillations with a specific amplitude, so that it bends at the extremities, subsequently lifting a weight over a short distance;

- A successful test can be concluded when no breaking of constituent wires of the tested dropper wire sample occurs before completing 2 million cycles;

- A full report is prepared including test object data, test description, set-up, procedure results and conclusions.