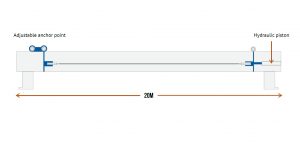

- Lamifil has a 500kN, 20m test bench which is digitally controlled and logged, improving test precision.

- We have experience with all conductor types (HTLS, composite core, GAP,…), railway products (catenary wires, feeders, …) and various anchoring types, including press fittings, epoxy/resin casts and wedge type clamps.

- We are fully flexible in the choice of fittings to be used and can advise based on experience.

- This test can be executed while running a current of up to 2000A through the conductor.

- The same set-up can be used for testing the accessories of the conductor.

- The conductor is mounted in between one static point and one movable point;

- Depending on the customer’s choice, the conductor is cast in resin or mounted in a fitting;

- Once mounted, tension is gradually increased and released again after each step;

- The steps (tension & duration) are defined in the applicable standard;

- A full report is prepared including test object data, test description, set-up, procedure results and conclusions;

- Usually this test is followed by a breaking load test.