By upgrading the existing ACSR conductor to an AAAC UHC Bobolink conductor we were able to reduce energy losses by 19%, resulting in an estimated annual saving of 678.000 euro.

Situation

AAAC UHC Bobolink for Tennet TSO

For TenneT TSO it was clear that the transmission capacity of the grid infrastructure between Zwolle and Groningen was going to be insufficient for handling imminent production increases.

The 220kV electricity connection needed to be upgraded to allow small-scale wind energy and combined heat and power (CHP) initiatives, as well as a new large-scale production facility to be connected to the high-voltage grid in the coming years.

As such, the question was not whether an upgrade needed to be installed. The question was what the best upgrade would be.

SUMMARY

AAAC UHC Bobolink

- Project Goal: Reduce line losses

- Type of Conductor: AAAC UHC Bobolink

- Conductor Length: 700 km

- Voltage: 220 kV

- Energized: 2012

Alternative required!

TenneT TSO initially looked at using ACSR Bobolink conductors. These conductors had often been used in the Netherlands and had a reliable track record. As a standard off-the-shelf product, they were readily accessible and available. But this did not mean they would meet modern standards for energy efficiency or environmental requirements. It encouraged TenneT TSO to evaluate whether there was a better option available.

TenneT TSO decided to open tenders for alternatives.

Any proposal would have to offer equal or better performance and mechanical strength with weight and diameter specifications no greater than those of the ACSR Bobolink (2476g/m and 23.24mm). TenneT TSO included a premium/penalty formula in their tender to guarantee the offered conductivity at point of delivery.

As an extra element in conductor selection, the total cost of ownership would also play a part in defining the best option for the project.

The solution – AAAC UHC Bobolink

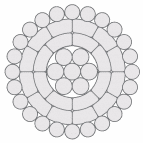

In response to the TenneT TSO demand, Lamifil developed the AAAC UHC Bobolink – an All Aluminium Alloy Conductor Ultra High Conductivity Bobolink. It combines layers of round and trapezoidal wires to improve transmission capacity and reduce loss. There is no increase on weight or diameter compared to the ACSR Bobolink.

TenneT TSO conducted a series of tests and examinations on the solutions tendered and also calculated the total cost of ownership. From the results, TenneT TSO selected the Lamifil AAAC UHC Bobolink.

They highlighted it for offering:

- the lowest total cost of ownership;

- increased transmission capacity;

- reduced CO2 emissions;

- compatibility with existing towers;

- conventional installation procedures.

Replacing the ACSR Boblink with an AAAC UHC Bobolink was expected to reduce losses by 19%.

Generation capacity requirements are expected to reduce by 1548kW, saving over 142,000 metric tons of carbon dioxide production over a 30 year period.

Based on current energy costs, savings of 678,000 euro per year are expected.

Conclusion

Improving the efficiency of conventional overhead conductors is becoming increasingly more important when upgrading existing lines. TenneT TSO is one of the leading companies in this respect and discovered that advanced ultra high conductivity conductors will not only reduce the total cost of ownership of their network but also help reducing CO2 emissions. Both resulting in serious savings.

Lamifil has extensive experience and expertise developing Ultra High Conductivity alloys with over 10000km of AAAC UHC lines installed.