The latest generation of GAP conductors are now here, offering radical new improvements.

SITUATION

National Grid – Gap conductor

Over recent decades Transmission System Operators (TSOs) and distributors of electricity (DSOs) have been faced with an increasing power demand, changing energy flows, emerging renewable power producers, and increasing regulation and restrictions on construction of new overhead lines.

National Grid UK faced such challenges when looking to increase the transmission capacity between, the 400kV substations Deeside and Daines, Heysham B (Power Station) and Stannah-Penwortham and Quernmore Tee-Penwortham.

Replacing the existing conductors with high performance conductors (HTLS) is a cost-effective, quick and reliable solution to deal with this challenge. With a broad range of options, Lamifil can propose the optimal technology for your particular project requirements.

SUMMARY

SUMMARY

- Project Goal: Increase capacity while fulfilling operating conditions

- Type of Conductor: GZTACSR Matthew

- Conductor Length: over 3500km

- Voltage: 400 kV

- Energized: between 2003 and 2015

ALTERNATIVES

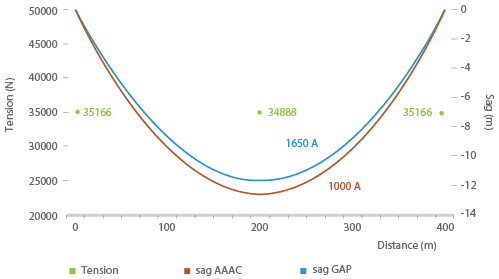

Whilst National Grid has increasingly moved away from conventional Aluminum Conductor Steel Reinforced (ACSR), to All-Aluminum Alloy Conductor (AAAC), the advantages of High Temperature Low Sag (HTLS) conductors are hard to ignore. Aluminum Conductor Steel Supported (ACSS) was eliminated due to sag and special suspension clamps, dead ends, and splices to avoid conductor damage. Gap conductors with trapezoidal, heat-resistant, Aluminium Zirconium alloy wires, around a steel core the best technical solution. This 50-year old technology has now been upgraded by Lamifil, making present day GAP conductors a cost-efficient high performance solution.

THE SOLUTION – LAMIFIL GZTACSR MATTHEW

For National Grid UK, Lamifil supplied the GZTACSR Matthew as a cost effective and reliable solution offering substantial benefits:

- Load transfer capacity increases by over 50%, matching the capacity of a triple AAAC with a twin GZTACSR operating at 170°C

- Operating temperatures can go up to 210°C

- No major modification required to the existing towers

- Lamifil’s patented installation method reduces installation time

- Our manufacturing expertise allowed specialised, high temperature Aluminium Zirconium alloys to be tailored to the conditions

CONCLUSION

National Grid UK has implemented over 3500 km of GAP conductor in the UK, with each installation increasing line capacity by over 90%. Lamifil has now further improved GAP conductors with the development of additional highly conductive high-temperature alloys, by using Mega high strength steel that allows us to maximise aluminium sections within a given weight and finally and by offering an emissivity of the surface of 0.6 or higher from Day 1.

Combine these advantages with the new patent pending installation technique that reduces extra installation time by 60% and TSOs now have one of the highest performing, most cost effective and reliable solutions ever.

SUMMARY

SUMMARY